How an Optical Fibre Diameter Analyser Improves the Performance of Fibre Optic Networks

How an Optical Fibre Diameter Analyser Improves the Performance of Fibre Optic Networks

Blog Article

Comprehending the Functionality of an Optical Fibre Diameter Analyser in Modern Manufacturing

The optical Fibre Diameter analyser serves as a crucial tool in modern manufacturing, providing exact, non-contact dimensions that are important for preserving rigid sector criteria. By leveraging advanced laser technology, these analysers not just make certain marginal signal loss yet also improve the general performance of optical fibres.

Significance of Optical Fibre Dimension

In modern-day production, the dimension of optical Fibre Diameter is vital for ensuring the performance and reliability of Fibre optic systems. Exact Diameter dimension straight affects optical performance, as variations can lead to boosted signal loss, reduced transmission capacity, and lessened total effectiveness. The optical residential properties, including light transmission and signal stability, are highly delicate to the Fibre's Diameter, demanding precise control throughout manufacturing.

Moreover, standardization in Fibre Diameter is essential for compatibility and interoperability within diverse telecommunications networks. As these networks increase worldwide, maintaining harmony in Fibre attributes promotes smooth integration throughout different components and systems. Furthermore, adhering to market requirements worrying Diameter resistances is vital for producers to fulfill regulative demands and customer expectations.

Purchasing sophisticated dimension technologies not just enhances making efficiency however likewise supports top quality assurance processes, making it possible for producers to identify defects early in manufacturing. This positive strategy reduces waste and makes certain that the end products fulfill strict efficiency standards. Consequently, the value of optical Fibre measurement can not be overstated, as it offers as a structure for premium, reliable Fibre optic systems, which are important to modern-day communication framework.

How Diameter Analysers Work

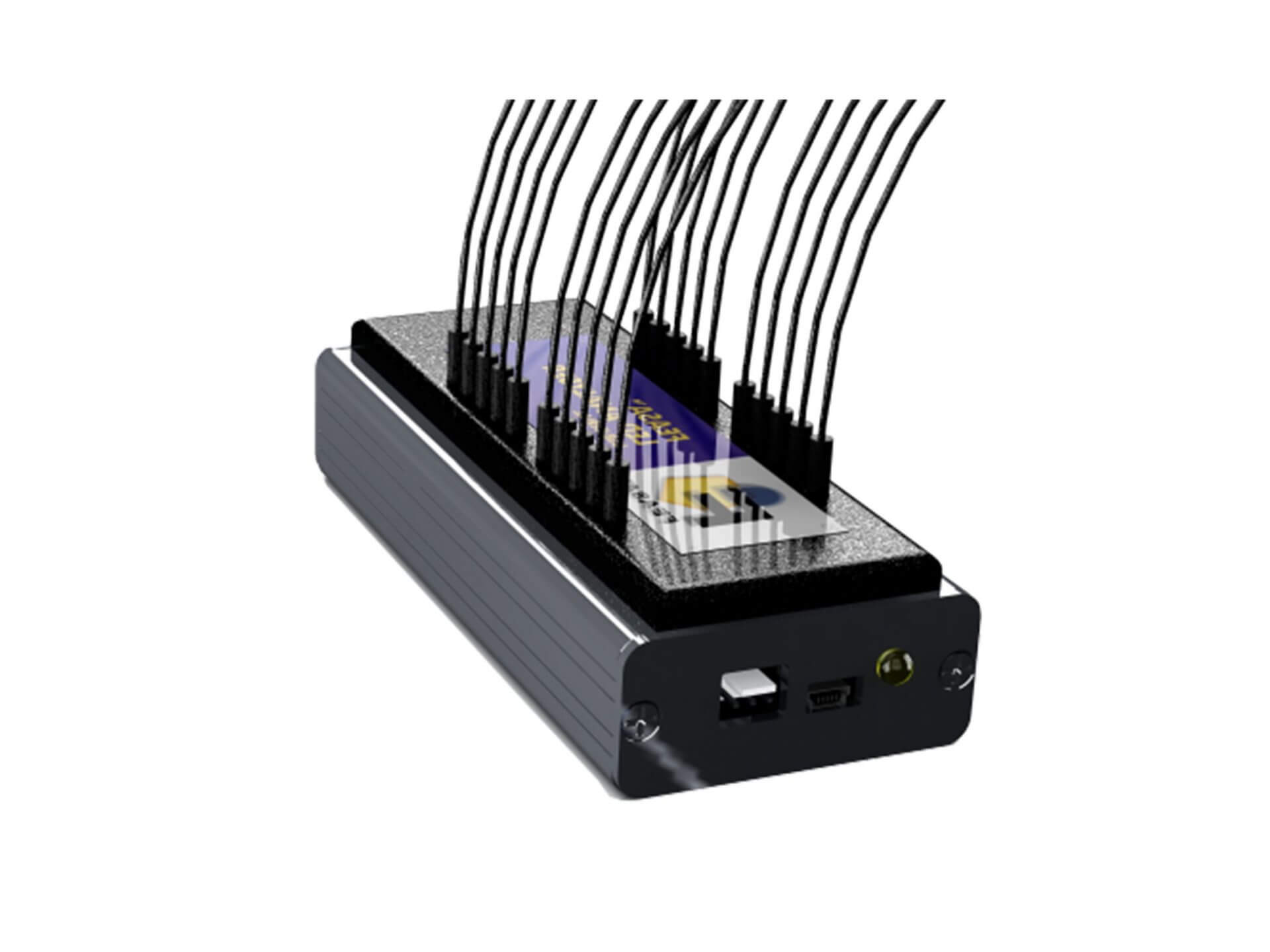

The core procedure counts on the principle of light scattering and reflection. As the laser light beam strikes the Fibre, variations in Diameter cause modifications in the light's intensity and wavelength (optical fibre diameter analyser). This information is refined in real-time using innovative formulas that equate the optical signals into specific Diameter measurements

Furthermore, numerous Diameter analysers are furnished with multiple dimension points along the Fibre, allowing for a thorough evaluation of Diameter uniformity. This is essential in making sure that the optical fibres meet rigid industry criteria. The entire process is automated, making it possible for high-speed measurements and reducing human mistake. The implementation of such innovation considerably enhances top quality control in manufacturing, making certain that optical fibres are created to specific specs for optimum performance in their designated applications.

Secret Attributes to Think About

When picking an optical Fibre Diameter analyser, a number of vital features require cautious factor to consider to ensure ideal efficiency and integrity. Initially, measurement accuracy is extremely important; the analyser should offer exact Diameter analyses, commonly in micrometers, to fulfill strict manufacturing specs. Additionally, a wide measurement array enhances flexibility, fitting various Fibre kinds and densities.

One more essential attribute is the analyser's rate. Fast measurement capabilities enable increased throughput, important in high-volume production settings. Real-time information handling and feedback capabilities make it possible for prompt changes, enhancing high quality control.

Interface and software program compatibility are likewise substantial factors to consider. An easy to use interface simplifies procedure, while robust software assistance assists in data evaluation and combination with existing production systems. The capacity to export data in different formats can improve reporting and conformity initiatives.

Additionally, sturdiness and maintenance demands should be reviewed. An analyser built from top notch materials will certainly stand up to the rigours of a manufacturing setting, while ease of upkeep makes certain longevity and reduces downtime. Take into consideration the level of technical assistance and training provided by the supplier, as this can substantially influence the effective use of the analyser in manufacturing setups.

Advantages in Manufacturing Effectiveness

Enhancing production performance hinges on the integration of sophisticated technologies, such as optical Fibre Diameter analysers. These instruments play an essential duty in making certain that optical fibres fulfill stringent high quality requirements, which is crucial for ideal efficiency in various applications - optical fibre diameter analyser. By offering real-time measurements of Fibre Diameter, makers can swiftly identify and correct variances from defined resistances, therefore lowering waste and minimizing the risk of defective products

Moreover, the early discovery of potential problems leads to reduced downtime and upkeep expenses, thereby enhancing source appropriation. Ultimately, the performance gets realized with making use of optical Fibre Diameter analysers add to a much more affordable manufacturing setting, making certain that business can deliver top notch items while preserving cost-effectiveness and responsiveness to market needs.

Applications Across Industries

The convenience of optical Fibre Diameter analysers expands beyond manufacturing performance, finding applications throughout numerous industries that depend on optical Fibre modern technology. In telecommunications, these analysers are critical for guaranteeing the optimum efficiency of Fibre optic cable televisions, directly affecting information transmission prices and network reliability. By precisely gauging Fibre sizes, operators can reduce signal loss and improve total i loved this interaction quality.

The medical sector additionally benefits considerably from these gadgets, specifically in the growth of endoscopic tools and laser treatments. Specific Diameter measurements are important for producing efficient optical fibres that are utilized in minimally invasive treatments, improving client results through boosted imaging and therapy capacities.

In aerospace, the analysers play a crucial role in the production of lightweight, high-strength products, where Fibre optics are incorporated right into architectural elements for tracking and diagnostics. In addition, the automotive industry news employs these devices to ensure the integrity of Fibre optic sensing units that enhance safety and efficiency features in automobiles.

Final Thought

In verdict, the optical Fibre Diameter analyser is vital for modern production, guaranteeing specific dimensions that support industry criteria. The diverse applications throughout various sectors highlight the analyser's significance in advertising continuous enhancement and data-driven decision-making within the manufacturing market.

In modern production, the measurement of optical Fibre Diameter is crucial for making sure the efficiency and dependability of Fibre optic systems. The relevance of optical Fibre measurement can not be overemphasized, as it serves as a foundation for high-quality, trustworthy Fibre optic systems, which are integral to contemporary interaction infrastructure.

Diameter analysers use innovative optical innovations to accurately gauge the Diameter of optical fibres.Furthermore, many Diameter analysers are furnished with multiple measurement factors along the Fibre, permitting for an extensive evaluation of Diameter consistency.The flexibility of optical Fibre Diameter analysers expands past visite site manufacturing effectiveness, locating applications throughout various industries that depend on optical Fibre modern technology.

Report this page